The 2018 State Science and Technology Awards Ceremony convened in the People’s Great Hall on the morning of Jan. 8th. Party and state leaders Xi Jinping, Li Keqiang, among others, attended the ceremony and conferred the awards.

Sichuan University has won six awards, of which four are the second prize of natural science and two are the second prize of technological invention. In addition, Sichuan University has participated in two achievements and won the second prize of the State Scientific and Technological Progress. The number of awards of our university is the eighth among all Chinese universities, and the number of awards SCU has won in the capacity of a first work unit (universal) ranks sixth nationwide.

The two second prize projects of the State Natural Science Award that SCU has led are:“New Algorithms of Pharmacophore Model-Based De Novo Design of Drug Molecules” by Professor Shengyong Yang and his team; “Fatigue Crack Initiation Mechanism and Life Prediction in VHCF” by Professor Wang and his team.

The second prize winners of the State Technological Invention Award are the project of “molecular complexsation to synthesizetriazineflame retardant and large-scale clean manufacture technology” by Professor Qi Wang and his team, and the project of "Efficient and Energy-Saving Separation Technology and Equipment for Closed Circulation Utilization of Fine Mineral Particles" by Professor Liangyin Chu's team.

In addition, Professor Yueming Song of West China Hospital of Sichuan University participated in "Innovation and Promotion of Key Technologies for Repair of Severe Spinal Trauma" and Professor Jianhai Zhang of Water Resource and Hydropower College participated in "Key Technologies and Engineering Applications for Safety Control of 300m Extra High Arch Dam". These two projects won the second prize of the State Scientific and Technological Progress.

Introduction of the award winners:

Second Prize of the State Natural Science Award

Title: “New Algorithms of Pharmacophore Model-Based De Novo Design of Drug Molecules”

Project principal: Shengyong Yang

The leading work unit: Sichuan University

This project belongs to the field of drug design and synthetic medicinal chemistry. They developed a set of new algorithms of pharmacophore model-based de novo design of drug molecules, and established many chiral catalysts including primary and secondary amines as well as various new synthetic methods. With these new algorithms and methods, they discovered a number of drug candidates. Five of them have been transferred to pharmaceutical companies, and one has entered clinical trials. Eight SCI papers have been cited for more than 770 times, and have been written into 26 authoritative books. 19 invention patents, including four international patents, have been authorized. They obtained six software copyrights. The project outcomes were selected in the "China's 100 most influential international academic papers in 2007" and the national top 100 doctoral theses in 2013, and was reported as “This week in therapeutics” by Science-Business eXchange (SciBX) of Springer Nature.

Second Prize of the State Natural Science Award

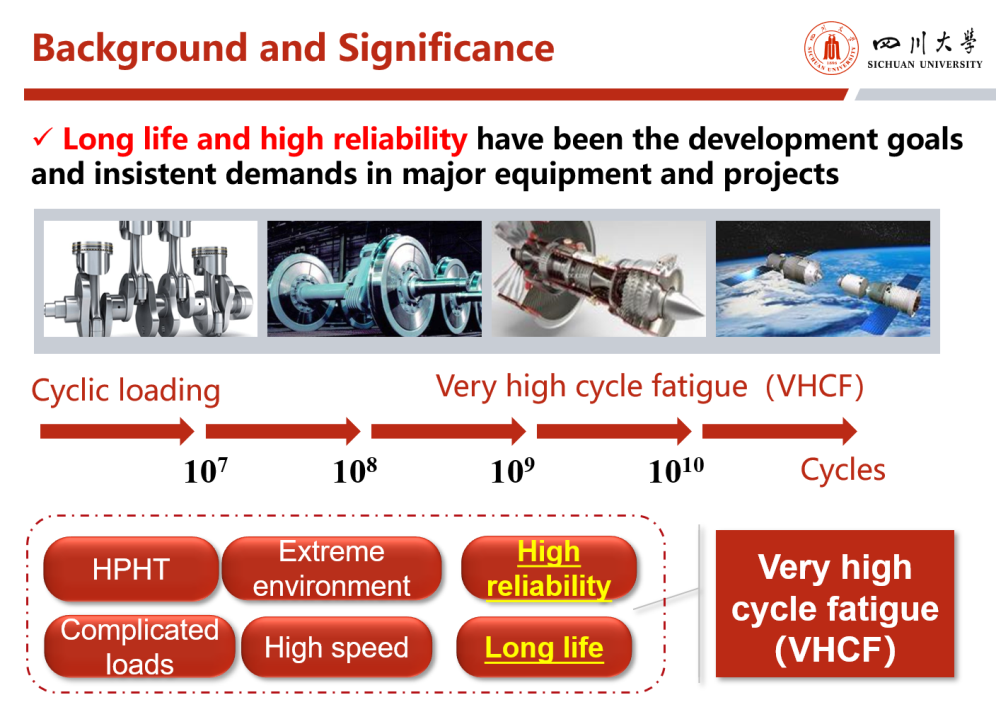

Title: Fatigue Crack Initiation Mechanism and Life Prediction in VHCF

Project principal: Qingyuan Wang

First leading unit: Sichuan University

The project aimed at experimental and theoretical investigations on super long life fatigue for over 20 years. The researchers of this project have successfully developed ultrasonic fatigue testing method and system with independent intellectual property rights, revealed internal fatigue crack initiation and failure mechanism in super long life regime, and proposed prediction models of total fatigue life and crack initiation life. The research achievements were widely cited by well-known scholars and highly appraised as “Finding of Wang……”, “Wang et al. provided the first experimental evidence”, “Wang et al. the first to discuss critically…”, “An exception is excellent work performed by Wang” etc. The project promoted the rapid development in the field of super long life fatigue in China. The research achievements have been applied in the design and manufacture of national major equipment and structures including ultra-supercritical steam turbine high-pressure rotor, aero-turbine engine compressor blade and box-girder bridge with corrugated steel webs, in which remarkable economic benefits have been gained.

Second Prize of the State Technological Invention Award

Title: Molecular Complexsation to Synthesize Triazine Flame Retardant and Large-Scale Clean Manufacture Technology

Project principal: Qi Wang

The leading work unit: Sichuan University

This project belongs to the field of plastics processing. In light of the urgent need for green and safe flame retardant plastics in national economy, the research team has invented molecular complexsation to synthesize triazine flame retardant and large-scale clean manufacture technology, reactive extrusion to produce triazine flame retardant and plastics, and processing technologies of synergistic triazine flame retardant plastics. As a result, this project has resolved a series ofworldwide technological problems in the fieldsuch as high reaction system viscosity, high water and energy consumption, and environment pollution in the preparation of triazine flame retardants, serious deterioration of material performance caused by addition of triazine flame retardants, as well as lack of multi-phase and multi-component flame retardant plastics processing technologies. In addition, the project has obtained 30 Chinese patents and 5 foreign patents. The production line with a capacity of 10,000 tons of triazine flame retardants has been established. Furthermore, more than ten halogen-free flame retardant plastics products have been manufactured. Moreover, their performance has reached the international advanced level. Having been widely applied in high-speed railway, new-energy vehicles, and national defense, this product has improved the technology in halogen-free flame retardant plastics industry.

Second prize of the State Technological Invention Award

Title: Efficient and Energy-saving Separation Technology and Equipment for Closed Circulation Utilization of Fine Mineral Particles

Closed Recycling and Utilization of Fine Mineral Particles, Efficient Energy-saving Separation Technology and Equipment

Project principal: Liangyin Chu

The leading work unit: Sichuan University

In this project, the researchers have invented new technology and equipment for hydrocyclone separation of fine mineral particles with high-efficiency and low-energy-consumption, as well as a short process technology for closed circulation utilization of fine mineral particles and pollution-free mines, with which the resource recovery and near zero-emission of fine mineral particles are realized. As a result, this project has obtained 53 patents, and set up three industry standards and has been incorporated in two national standards. More than 100,000 sets of equipment based on these technologies have been employed in mines of irons, coals, non-ferrous metals and non-metallic minerals, with a domestic market share of 78%. They are also exported to 40 countries including Australia. This project has cut down on the amount of fine mineral particles by turning fine mineral pollutants into useful resource, achieving a major breakthrough in efficient and clean production in mining industry. It has significantly benefited the society, economy and environment.