Professor Yi Yang's team has made new progress in field modification technology recently. The research results were published in Tribology International in an academic paper entitled "Enhancing Tribological Performance of Cemented Carbide (WC-12Co) by Pulsed Magnetic Field Treatment and Magnetofluid”. The paper’s first author is Yongfeng Yang, a doctoral student; and Dr. Mingxia Wu is the corresponding author.

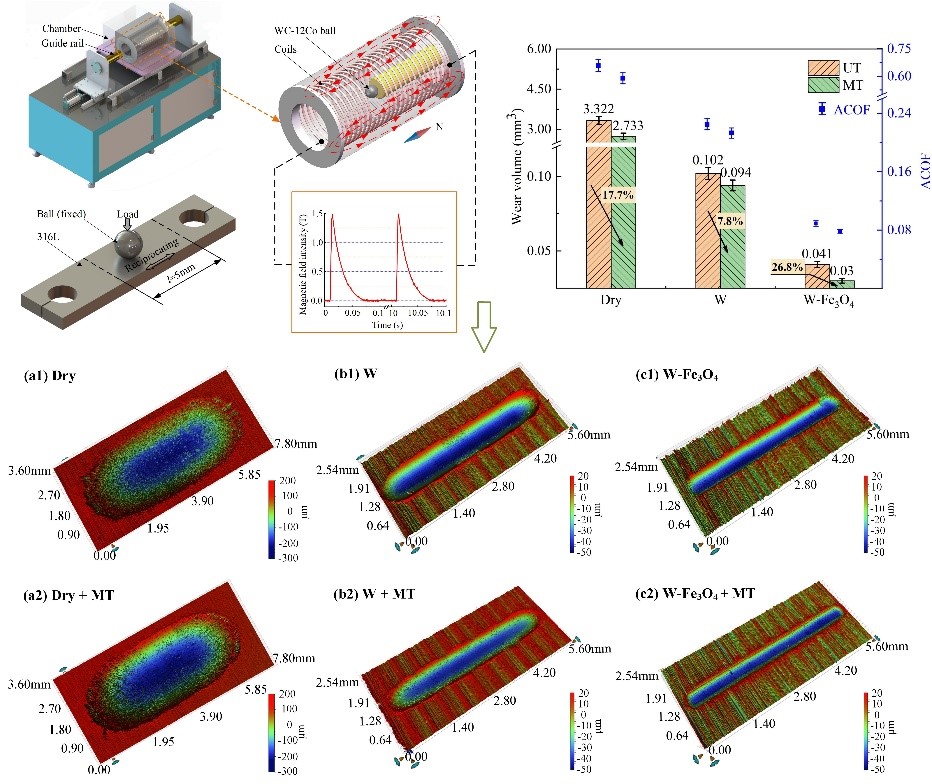

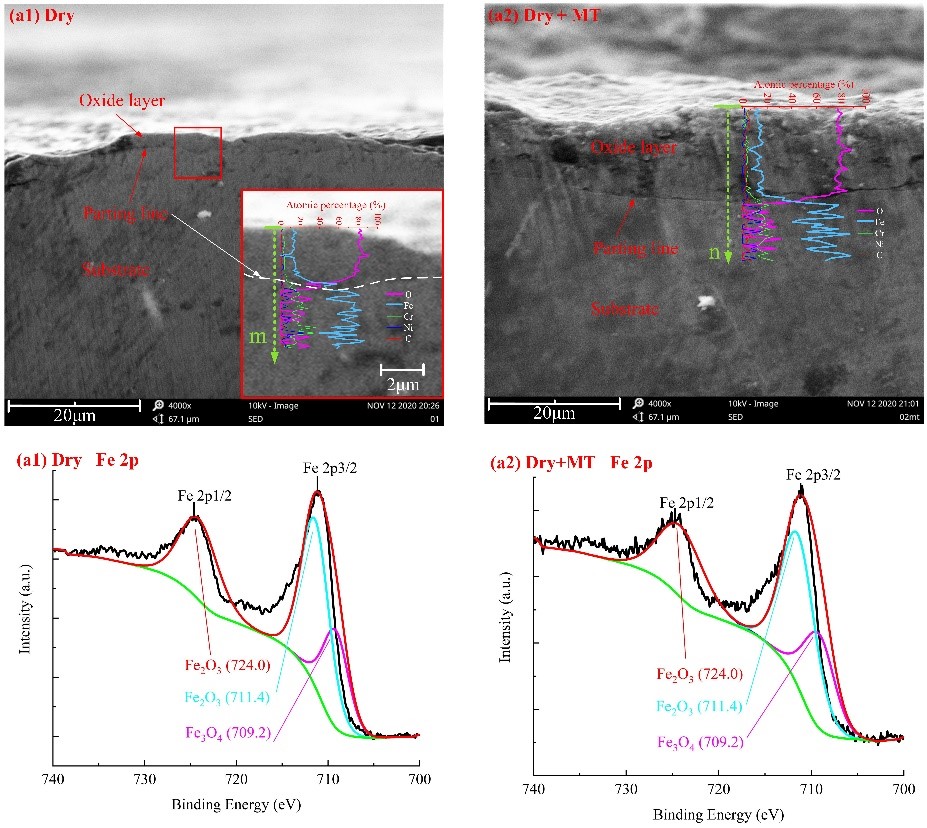

“Pulsed magnetic field treatment was applied to the cemented carbide (WC-12Co) for enhancing its friction-reducing and anti-wear effect under different friction conditions, including dry, distilled water and nano-Fe3O4 particles additive friction. The results show that the friction reduction and anti-wear effect could be enhanced with pulsed magnetic field applied. Especially, with nano-Fe3O4 magnetofluid lubrication, the wear volume of workpiece is reduced by 26.8% and the average friction coefficient is reduced by 12.4%. The effect of the pulsed magnetic field on tribological properties is closely related to the oxidation and remanence. It can promote oxidation and forms a protective layer on the friction pair. Furthermore, it can make magnetofluid gather and amplify the lubrication.” (Abstract)

Schematic diagram of magnetic field treatment and wear morphology change of workpiece

Features of cross section and surface composition of workpiece

https://doi.org/10.1016/j.triboint.2021.107086