In cooperation with Professor Yuntian Zhu of North Carolina State University, and the research team of Xiaolei Wu, a research fellow of Institute of Mechanics, Chinese Academy of Sciences, the reserch team of Professor Chongxiang Huang of School of Aeronautics and Astronautics, Sichuan University has made important research progress in plastic deformation and toughening mechanism of isomeric metal materials. The results have been published consecutively in International Journal of Plasticity ( IF=5.8, 2018 ) in two articles of “Dense dispersed shear bands in gradient-structured Ni” and “Extra strengthening in a coarse/ultrafine grained laminate: Role of gradient interfaces”.Yanfei Wang, a class 2016 Ph.D. student atSchool of Aeronautics and Astronautics, Sichuan University, is the first author of the paper, while Professor Chongxiang Huang and Professor Yuntian Zhu are the corresponding authors.

Microisomeric control is a new concept of metal material design in recent years. This concept regulates the mechanical incompatibility between components at different scales from macro to micro, so as to promote the interaction between components under load conditions, so as to stimulate the mechanical properties of heterogeneous elements at the same time and make the materials show high strength and toughness as a whole. In the past five years, some academic work has found that heterogeneous materials have better performance than those predicted based on the mixing rule, and two key basic common problems have been raised: ( i ) Can heterogeneous materials indeed produce additional strengthening and toughening effects, and what is the physical mechanism of this effect? ( ii ) How can high-strength elements in heterogeneous materials achieve large plastic deformation?

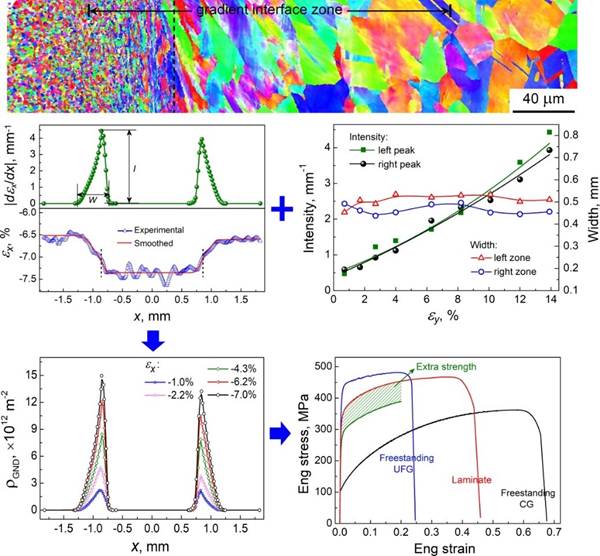

For the first key common problem, the team designed model materials with only three component layers, using high precision digital speckle technique ( DIC ) and transmission electron microscopy ( TEM ) to focus on the strain and dislocation behavior at the interface of the unit layer, thus revealing the mechanism of additional strengthening and toughening.The results show that heterogeneous materials do have a very large additional strengthening effect, which originates from the accumulation of strain gradients and geometrically necessary dislocation accumulation at the interface caused by the synergistic constraints between mechanically incompatible elements.

Figure 1. Additional hardening effects in layered materials due to accumulation of interfacial strain gradients and dislocation plugging

In response to the second key common problem, the team used Nano crystalline-coarse-grained gradient materials as models to characterize the strain distribution and evolution of gradient materials during plastic deformation using micro-scale DIC technology. The findings show that the high-strength Nano crystalline layer can achieve excellent uniform and large plastic elongation in the form of high-density dispersive shear bands due to the synergistic constraints of coarse-grained unit layers. Based on the analysis of the mechanism of shear band initiation and strain accommodation, a theoretical model is proposed for the first time to promote the formation of dispersive shear bands and maintain plastic stability under the interaction constraints of heterogeneous elements. In addition, the formation of DSB in Nano crystalline materials is a new discovery, which provides a new way to overcome the problem of low elongation of Nano crystals.

Figure 2. NS-CG gradient materials plastic elongation by means of diffusion shear band deformation

This research was funded by the National Key Research Program ( 2017YFA0204403 ), Key Project( 51931003 ) and General Projects ( 11672195、51741106 ) of the National Natural Science Foundation of China.

Articles links: https://doi.org/10.1016/j.ijplas.2019.07.019